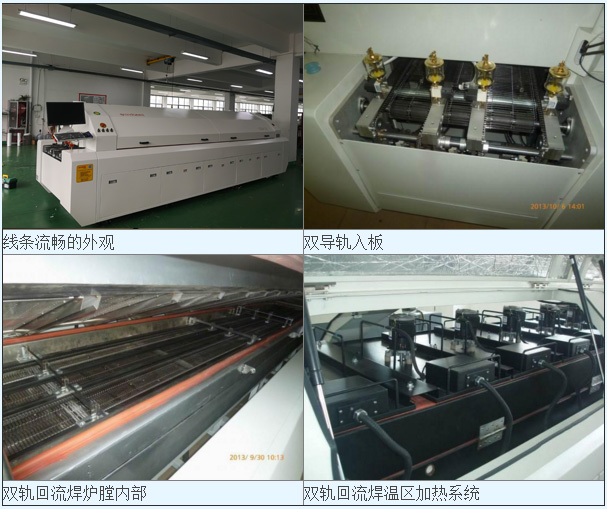

The independent transportation of dual rails enables two different models of products to be reflow soldered on the dual rails at the same time, and the production efficiency can be doubled;

0563-2251668 / 15850207552 在线咨询The detailed structure of the large-scale dual-track reflow soldering equipment of Guangshengde

Performance advantages of Guangshengde large-scale dual-track reflow soldering equipment

● The independent transportation of dual guide rails enables two different models of products to be reflow soldered on the dual guide rails at the same time, and the production efficiency can be doubled;

● In order to prolong the service life of the motor, our company’s technicians professionally designed it; make the internal cooling cycle convection, so that the temperature around the motor drops to about 38°C;

● The high-quality, high-temperature, high-speed motor has smooth wind, low vibration and low noise;

● Professional wind wheel design, stable wind speed, effectively prevent the uniformity of the wind when the PCB board is heated, and achieve higher repeated heating;

● Each temperature zone adopts forced independent circulation, independent PID control, and upper and lower independent heating methods, so that the temperature of the furnace chamber is accurate and uniform, and the heat capacity is large; the high-tech heating method solves the problem of dead corners during reflow soldering. Suitable for CSP, BGA, 0201CHIP and other electrical components welding;

● Online UPS equipped with power failure protection function to ensure the normal output of the PCB board after power failure without damage;

● Independently controlled cooling system, made of imported stainless steel, upper and lower cooling convection, the cooling curve is a mirror image of the welding temperature curve, which is in full compliance with the SMT international certification standard.

● The insulation layer is made of high-quality aluminum silicate insulation material, and the multi-layer insulation furnace design. The surface temperature of the furnace outer jacket is about 5 degrees higher than the ambient temperature, which effectively reduces the working environment temperature, has good insulation effect, and heats up quickly, from room temperature to working temperature. ≤20min; Special furnace design, power consumption is the lowest in the industry;

special reminder

1. Guangshengde reflow soldering equipment is underwritten by Ping An Insurance Company of China, and the amount of compensation can reach 5 million. Guangshengde reflow soldering brings greater guarantee for customers' safe production.

2. The purchase of Guangshengde reflow soldering equipment can be paid by monthly installments, please consult Guangshengde for details.

Technical parameters of Guangshengde large-scale dual-track reflow soldering equipment GSD-L8H

Control system: computer + PLC (Windows 10);

Computer system: Windows 10 system;

Operation control interface: Chinese and English online free switching;

System control mode: PC+PLC+PID+SSR+ temperature control module;

Equipment and personnel safety: set up leakage protector;

Alarm function for high or low temperature: standard configuration;

Timing refueling: the computer automatically refuels and lubricates the chain;

Real-time monitoring and recording: daily user operation record log files are generated;

Temperature curve graph of temperature zone: Generate temperature curve graph files of each temperature zone every day, and users can view and analyze the temperature trend of each temperature zone;

Temperature curve test: The system has the function of temperature curve test, and analysis is made according to the curve;

Abnormal alarm mode: high temperature or low temperature abnormal alarm;

Heating zone: 16 heating zones in the upper 8 and the lower 8;

Length of heating zone: 3200mm;

Heating time: the starting time from normal temperature to temperature equilibrium is about 20 min;

Temperature control range: room temperature~300℃;

Temperature control accuracy: ±1~2 ℃;

Three-point temperature difference: ±3℃;

Number of cooling zones: Standard configuration with 4 cooling zones on top 2 and bottom 2;

Cooling method: air cooling;

Wind speed adjustment: layered, variable frequency adjustable;

Exhaust air volume: 2000m?/h-2500m?/h;

Sound level in decibels: below 60 decibels;

Power failure protection: UPS power supply;

Power supply: A3?380V 50HZ;

Normal operating power/total power: 11/73KW;

Body size (L*W*H): 5530 mm(L)*1650 mm(W)*1500 mm(H);

Net weight: 2350 KG.

Guangshengde large-scale dual-track reflow soldering equipment GSD-L8H heating component configuration parameters

Hot air motor: high temperature resistant long-axis motor with a speed of 2800rpm, adopts frequency converter speed regulation technology, and carries out stepless speed regulation of all hot air motors from 0 to 2800 rpm;

Heating element: special long-life winding heating wire, high thermal efficiency and sensitivity, low thermal inertia;

Air duct structure: Guangshengde special high-efficiency acceleration turbine + volute double duct structure to provide sufficient circulating air volume;

Flux and flue gas recovery: forced exhaust device, the whole process of flux and flue gas recovery, to ensure that the flux and flue gas do not leak.

Guangshengde large-scale dual-track reflow soldering equipment GSD-L8H transmission component configuration

High-strength torsion resistant guide rail: high-strength hardened guide rail is sturdy and durable;

Transport chain structure: long-axis carbon steel chain;

The extension length of the conveyor chain: standard 4.8mm;

Transport motor: three-phase Toho variable-frequency speed-regulating motor;

Chain lubrication method: computer controlled lubrication, users can set the cycle and drip time (provide better lubrication effect for the transportation chain);

Mesh belt configuration: 700mm wide stainless steel mesh belt, running synchronously with the chain.

The body structure of GSD-L8H large-scale dual-track reflow soldering equipment

Frame structure: the overall frame welded structure, sturdy and durable;

Door structure: All are detachable structures, providing maximum maintenance space;

Opening method of upper furnace body: Double electric linear drive jacking rod, with self-locking function, safe and reliable;

Top cover opening method: self-made special support for easy cleaning.

Guangshengde large-scale dual-track reflow soldering equipment GSD-L8H is suitable for PCB board requirements

PCB size: (W) 50 ~ (W) 250mm;

Transmission mesh belt width: 700mm;

Chain track width adjustment range (dual track): 50~250mm;

The height limit of the components on the PCB: upper 30mm and lower 25mm;

Transmission speed: 0~2000mm/min variable frequency adjustable;

Transmission direction: left→right;

Transmission method: double chain track + mesh belt transmission;

Track fixing method: 1-3 fixed or 1-4 fixed (customized);

PCB transmission height: 900±20mm.