Fully automatic lead-free wave soldering machine GSD-WD350CE preheating part details

0563-2251668 / 15850207552 在线咨询Fully automatic lead-free wave soldering machine GSD-WD350CE preheating part details

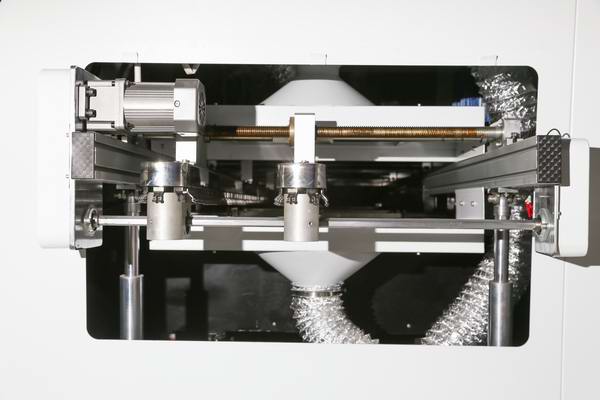

Fully automatic lead-free wave soldering machine GSD-WD350CE release mechanism diagram

Automatic wave soldering GSD-WD350CE electrical control diagram

Features of spray system of automatic lead-free wave soldering machine GSD-WD350CE

● Adopt Lumina nozzle, spray range 20~65mm, adjustable fan, height 50~80mm adjustable, flow rate 60ml/min.

● Imported filters, control valves and pipe joints are used, and the air pressure is displayed digitally. The air pipes of all spray systems adopt acid and alkali resistant, corrosion-resistant SMC air pipes.

● The flux spray system adopts the scanning spray method, which uses the limit proximity switch and the board entrance light to control the combination. According to the speed and width of the PCB, the PCB is automatically detected by the sensor spray. To achieve the best effect of the wetting range of the flux, imported nozzles and stepping motors, dedicated drive control system, accurate and reliable;

● Stainless steel is used as a tray under the nozzle, which is used to hold waste water and flux, which can be taken out and cleaned at will;

● The exhaust system is filtered by double-layer stainless steel wire mesh, using the characteristics of the fluid to filter and recover excess flux.

● Equipped with adjustable direction and air pressure air knife to blow the excess flux during spraying into the recycling box to prevent the flux from entering the preheating zone and ensure production safety.

● All stainless steel bracket, easy to clean and maintain. High anti-corrosion grade and durable.

Features of welding system of automatic lead-free wave soldering machine GSD-WD350CE

1. The PCB board enters the soldering area of ??the tin furnace, and the soldering starts automatically, and the wave crest is automatically stopped after the soldering is completed.

2. Lead-free and environmentally friendly independent design of the tin furnace, lifting and in and out, convenient and safe, and easy to clean;

3. The tin furnace is made of high-quality imported stainless steel, and the aluminum silicate insulation material is insulated. When the temperature inside the furnace is 270°C, the temperature outside the furnace is ≤60°C, which has good insulation effect and high safety.

4. 3MM thick lead-free stainless steel material, high temperature and corrosion resistance, adapt to lead-free process, long life; a furnace is standard.

5. The tin furnace adopts a 5-side heating method, which heats up quickly, and is designed with automatic on/off time. The tin furnace can be produced after 70 minutes of heating time.

6. The tin furnace adopts imported high temperature motor, stepless frequency conversion speed regulation, independent control, stable peak performance;

7. The heating of the tin furnace adopts high-speed PID external heating type two-stage independent control, and the temperature rises rapidly, which solves the shortcomings of the tin furnace explosion;

8. The nozzle of the tin furnace can be adjusted according to the width of the PCB board you want to pass, which reduces the area of ??the ineffective soldering area, keeps the solder and air contact area small, and greatly reduces the amount of solder oxidation. The impurity of the tin bar is different from the tin dross. Suitable for various lead-free solders of Sn/Ag/Cu, Sn/Zn, Sn/Cu, and the oxidation amount of tin dross is within 0.8-2.0KG every 8 hours (depending on the size of the PCB board)

9. Increase diversion trough and anti-oxidation sleeve to reduce black powder and bean curd dregs oxide.

10. The design of the tin furnace is reasonable, and the tin slag is automatically collected. It is simple, convenient and safe to clean the tin furnace.

It can be cleaned once a week or longer according to the situation without having to pick up the tin slag every day.

Compared with other wave soldering of Guangshengde, the main feature is equipped with an automatic tinning device and an automatic operation system for enhancing wave soldering. The tin furnace capacity is 500KG

| project | Specification type |

| way to control | Computer + PLC (Guangshengde PCBASE wave soldering control software V1.0) |

| Transport motor | 1P AC220V,60W |

| Transportation speed | 0~2000mm/min |

| Substrate size | 30~450mm(W) |

| Flux capacity | 6L |

| Preheating zone | 1800mm three-stage control, independent ventilation, room temperature~250℃ |

| Tin furnace heating | 1KW * 12PCS Room temperature~300℃ |

| Tin furnace capacity | 500KG |

| Crest height | 0~16MM |

| Crest motor | 3P AC220V,0.18KW * 2PCS |

| Claw washing pump | 1P AC220V 6W |

| Transport direction | Left → right |

| Welding angle | 3 ~ 6 º |

| Flux air pressure | 3 ~ 5 BAR |

| power supply | AC380V 50HZ |

| Normal operating power/total power | 8KW/25KW |

| Dimensions | 4470(L)*1550(W)*1700(H)MM |

| Dimensions | 3800(L)*1550(W)*1700(H)MM |

| net weight | 1380KG |

| Canadian way | Equipped with automatic tinning device |